Systems

Commercial

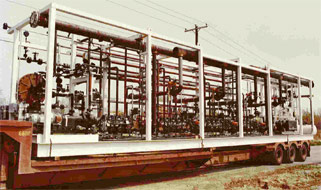

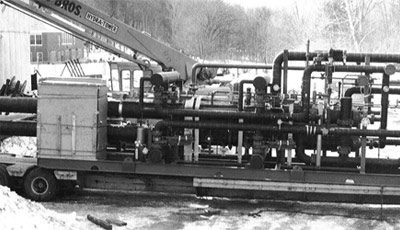

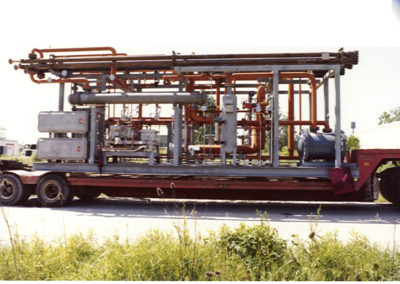

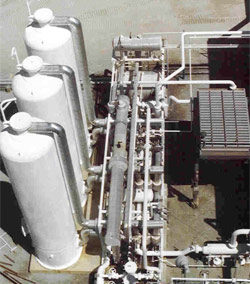

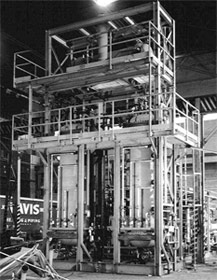

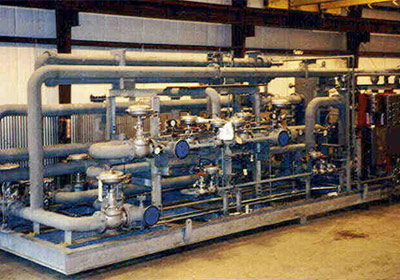

Commercial Systems

Chemical Design, Inc. supplies custom designed, commercial systems around the world using adsorption technology for purification and separation applications. Our proven adsorption expertise can provide customized solutions across all industrial sectors.

Hydrogen & Syngas

Adsorption systems for any product specification up to 99.9999% pure »

Chemicals

Specialty chemicals purification and drying, phosgene production »

Petrochemicals

Hydrocarbon purification and drying »

Natural Gas

Pretreatment to remove contaminants prior to liquefying »

Air Separation

As the first to use molecular sieves in a large scale commercial air separation plant »

Vent Gas Recovery

Silicon production generates valuable vent gas streams that can be recovered and recycled »

All Systems

Leader in Adsorption Processes

What is Adsorption?

Adsorption is when a gas or liquid fluid phase containing one or more contaminants (adsorbates) comes in contact with the surface of an activated solid (adsorbent) that has the property of attracting the contaminants present in the fluid phase. The process of concentrating the adsorbates on the solid surface is called adsorption and the reverse process is desorption or regeneration.

Adsorbents are characterized by polarity and surface area. Adsorption is physically caused by van der Waals forces and electrostatic forces between the contaminants you want to remove and the adsorbent surface. Surface area and the size of the micropores on the adsorbent determine the accessibility of the contaminants to the internal adsorbent surface. Adsorbents can be specifically engineered to eliminate certain molecules entering with precise pore size to allow specific contaminant entry.

There are a number of different adsorbents commercially available such as molecular sieves, silica gels, activated carbon, alumina, natural zeolites, etc. Each adsorbent has specific adsorption characteristics, when coupled with the precise pore size, provide very targeted contaminant removal.

Contact Chemical Design Today

Adsorption processes can be used for purification of gases and liquids or bulk separation of gases. For the last 60+ years, Chemical Design has focused our efforts on adsorption purification. We have been a leader in applying temperature swing adsorption techniques for purification and separation applications for gases and liquids. Contact us to discuss the benefits of using adsorption processes to purify your gases and liquids.